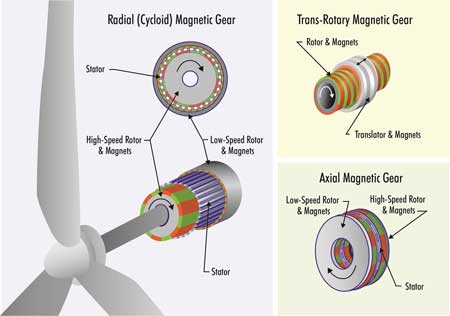

Exploring New Technologies for Extreme-Scale Turbines

Exploring New Technologies for Extreme-Scale Turbines

Larger turbines – beyond today’s multi-megawatt onshore and offshore machines – are one of the most attractive options for reducing the cost of wind energy. Continued technology scale-up to rated capacities of 10MW and beyond requires novel concepts for overcoming the fundamental limitations of today’s turbine designs and materials, including structural constraints of drive-train components. This article explores how magnetic gearbox technologies could provide solutions.

By Luis Cerezo, Technical Executive, EPRI, USA