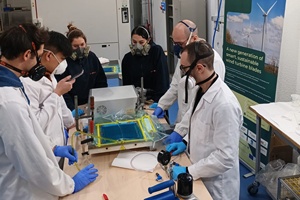

The EU-funded EOLIAN project has completed infusion trials demonstrating the manufacture of basalt fibre reinforced vitrimer composite laminates for wind turbine blades. Project partners Proplast and Politecnico di Milano produced laminates using an infusion process compatible with current blade manufacturing methods, marking progress towards the production of a 12 metre vitrimer composite demonstration blade.

The EU-funded EOLIAN project has completed infusion trials demonstrating the manufacture of basalt fibre reinforced vitrimer composite laminates for wind turbine blades. Project partners Proplast and Politecnico di Milano produced laminates using an infusion process compatible with current blade manufacturing methods, marking progress towards the production of a 12 metre vitrimer composite demonstration blade.

The project focuses on developing composite materials that combine a bio-based vitrimer matrix with natural basalt fibre reinforcement to provide repairability, reprocessability and recyclability while maintaining performance requirements for wind turbine blades. The work addresses the limitations of conventional glass fibre reinforced thermoset composites, which are difficult to recycle and offer limited end-of-life options.

Tekniker is leading the synthesis of imine-based vitrimer formulations derived from sustainable building blocks such as vanillin and epoxidised vegetable oils. The project has developed vitrimer matrices with around 60% bio-based content that maintain vitrimeric behaviour and thermo-mechanical properties while remaining suitable for infusion processing. The materials are designed to be reprocessable, repairable and recyclable under low temperature and pressure conditions without specialised equipment.

Infusion trials conducted by Proplast and the Polymer Engineering Lab at Politecnico di Milano addressed challenges related to high viscosity and short pot-life typical of vitrimer systems. The project team successfully manufactured high-quality laminates at moderate temperatures ranging from room temperature to 80°C, achieving optimised fibre volume fractions and low void content.

Alongside materials development and testing, the project is developing structural health monitoring systems using in-mould electronics to embed erosion and ice detection sensors within the composite structure. Norvento Enerxía is preparing to manufacture a prototype sensor-assisted vitrimer composite blade, which will be benchmarked against a traditional glass fibre epoxy blade. The comparison will include a levelised cost of energy analysis and a life cycle assessment to evaluate performance, sustainability and manufacturing impacts.

Picture courtesy Proplast / EOLIAN